3D printing: Treating the previously untreatable

Hershey, Pa. – Doctors at Hershey Medical Center were faced with a unique challenge – helping a newborn with a rare condition that prevented her from breathing on her own.

There were few documented cases of tracheal agenesis, a birth defect where the windpipe is missing or underdeveloped, and the long-term survival rate is low.

But using 3D printing, the surgeons were able to design a splint to support the girl’s esophagus to allow her to breathe on her own.

“When you look at the scale of a three-month-old, it hits home to the difficulty of the problem,” said Dr. Randy Haluck, MD, surgery professor and vice chair of innovation and technology at Penn State Health. “There’s no way we could have addressed this without that degree of surgical planning and that technology we’re talking about today.”

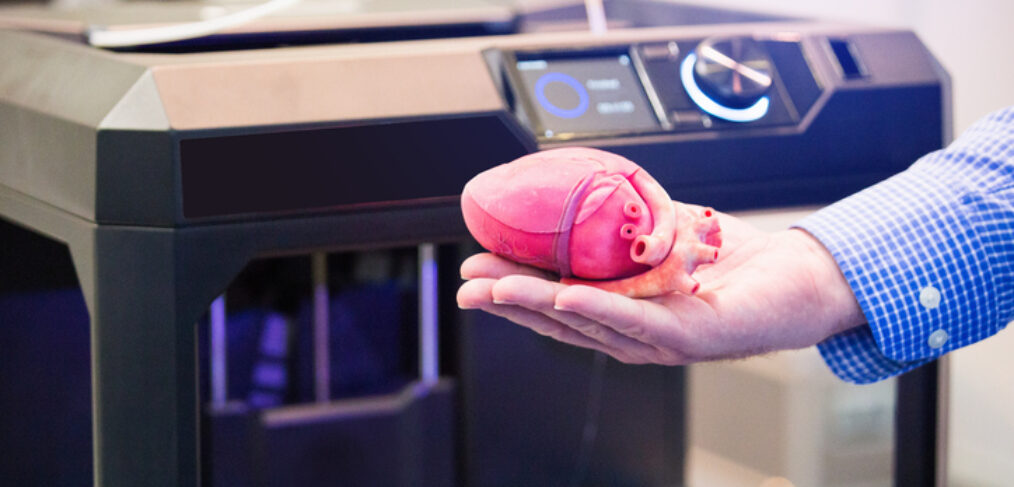

3D printing technology is giving health care providers new tools to fight disease, and developments in bioprinting have the potential to save lives by creating tissue and even organs.

Currently 3D printed models are used heavily in patient and family education, but probably the most robust use is in surgical planning.

“It’s really personalized surgery,” Haluck said. “Through images, we can see the existing state, plan for the future state, and through software show how we can move things around, even by a millimeter.”

Alyssa Glennon is a principal engineer for business development at Materialise, a Belgium-based company that provides 3D printing services for the auto, aerospace and health care industries. In health care, she said 3D printing is growing most quickly in orthopedic uses because the bone is easy to isolate in 3D imaging, but the technology is being increasingly used in cancer and cardio-vascular treatments, particularly for pediatric patients.

“When your heart is the size of a walnut, clinicians and nurses must understand the valve issues – how big they are and how they can get there,” she said.

The Tangible Differences

The first 3D printers were built in the 1980s, but it was only in the last few years that 3D printing became more widely understood as affordable consumer printers hit the market. Today, 3D printing technology has been used to make everything from medical implants and auto parts to houses, and, controversially, even guns.

Glennon said many people think of 3D printing like printing a document, but it is actually much more complicated.

Radiologists capture 3D images through CT or MRI scans. Software then converts the image into a digital file where engineers can isolate the area of interest. Before you can press the “print” button, you have to consider the end use and what materials need to be used.

“Some types of devices, you can do overnight. I set it up at night and when I come back in the morning It’s done,” Glennon said. “Pelvis implants that are large make take a full day. If they require post-processing, it may take a full week.”

Her firm assisted in developing 3D models for surgeons at the Children’s Hospital of Philadelphia who performed the world’s first pediatric bilateral hand transplant. The story of the Zion Harvey, a 9-year-old who lost his hands to an infection, made international headlines.

“The key to 3D printing is it helps you treat the previously untreatable. Maybe it gives the clinician confidence, where historically they may have done more palliative care,” Glennon said. “To give someone hands again – to scratch your nose or share a sandwich with friends – these are the tangible differences you can make with 3D printing.”

The ‘Holy Grail’

In recent years, 3D printing has started shifted increasingly to the actual point of care.

“The industry does as good a job as they can, but they never have every size of every device. If you bring 3D printing to the point-of-care, it’s much faster and more available,” Glennon said.

Haluck imagines a scenario where a patient undergoes an imaging scan and when he or she returns next week for a follow up appointment, their device is printed and ready to be used.

“As clinicians start to use these systems, the ideas are just going to flow. We’re going to be on the curve of creativity,” Haluck said. “Right now it’s used mostly for bony-type structures. But we’ll start getting creative in tissue-type surgeries.”

Tissue and organ applications represent the “holy grail” for 3D printing research, according to Dr. Guha Manogharan, assistant professor in the Department of Mechanical and Nuclear Engineering, Penn State University.

Bioprinting, or using 3D printing techniques to create biomedical parts like tissue, is a rapidly emerging field of research. Scientists have developed two main types of bioprinting – scaffold-based and scaffold-free printing.

The scaffold approach is “basically like building a house,” Manogharan explained. The patient’s cells are printed into a scaffold shape using a gel. The gel is later dissolved, leaving only the tissue.

It is this method that Penn State researchers used when they looked for ways to grow replacement tissues in a reliable, cost-effective way. Their research, published last year in Advanced Healthcare Materials, provides a framework for growing living tissue with a hobby-grade 3D printer.

Haluck said the need for organs is driving much of the research in 3D printing. Every year, thousands die while waiting on the transplant list for a suitable organ.

“That’s the hope – that we can print these organs. Would a kidney look like a kidney? Maybe not. Maybe the kidney tissue lives off blood supply from the bowel and can sustain life and keep someone off dialysis,” he said. “It may be a long time before we can get something that looks like a kidney, but there are likely useful interim steps.”

In 2006, researchers at Wake Forest reported on the first human recipients of lab-grown organs. The study showed that the lab-grown bladders functioned as well as bladders repaired with traditional methods that used a section of intestinal tissue, but more research is needed.

“That is the holy grail, but there are a lot of steps we’re able to do now that are very valuable,” Glennon said. “If you can visualize where a tumor is, you can 3D print a model that so surgeons can plan how to get there, how to resection this and save as much of the organ while still removing the cancer.”

This blog post was a writing assignment for my science writing class at Penn State based on a health care innovation event at Penn State College of Medicine.